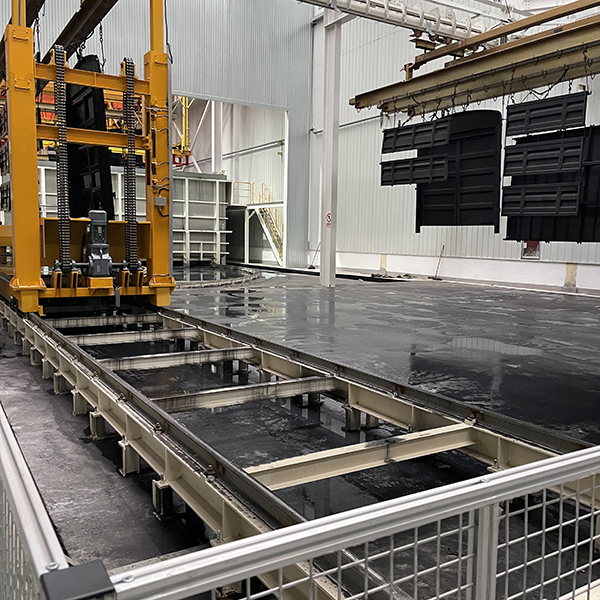

Cathodic Electrodeposition ED Painting Line

Components of electrophoretic coating line

Electrophoresis equipment (electrophoresis tank, spray tank, electrophoresis power supply, electrophoresis recovery ultrafilter, electrophoresis coating equipment)

Electrophoretic paints (color electrophoretic paint, cathodic electrophoretic paint, anodic electrophoretic paint) are available in matte, flat, high-gloss and color, and their performance is at the advanced level of the same products in China.

They are widely used in the corrosion-resistant coating of automobiles, household electrical appliances and all kinds of steel parts.

Product Display

The ED painting lien equipment mainly includes

Electrophoresis tank (main tank)

The electrophoresis tank is filled with electrophoresis liquid, and the coated objects are electrophoretically coated in it. The capacity of the tank is determined by securing the target film thickness, and all other equipment for electrophoretic coating serves this tank. The tank is divided into a main tank and an auxiliary tank to ensure film generation (penetration, film thickness distribution, etc.), and the tank liquid overflows from the discharge section to the auxiliary tank.

Tank liquid circulation and agitation system

The tank liquid is blown out by the tank liquid circulation nozzle installed at the bottom of the tank to carry out in-tank mixing to keep the paint in the tank uniform, prevent pigment from settling, cool down the heated painting surface, and remove the spreading electrolytic bubbles, which consists of the circulating pump, the in-tank piping, and the blowing nozzles, etc. The nozzles are made of plastic and are used outside of the tank. The nozzle is made of plastic and the piping outside the tank is made of stainless steel to prevent galvanic corrosion.

Filtering device

Coarse filter: Filter out the foreign matter falling into the tank to protect the circulating pump.

Precision filter: Remove the dust and particles in the tank liquid to reduce the coating dust and particles on the body surface. Mostly use metal outline type, mostly use fiber system, through the large area of the cylinder roll or bag type.

Heat exchanger

Heat exchanger exchanges the heat converted from the electrical energy of electrocoating and the mechanical energy of the pump work to ensure that the temperature of the tank liquid is stabilized at < 28 +1)℃. As an anode heat exchanger for cathodic electrophoresis, it is installed in the circulating pipeline of tank liquid and adopts plate heat exchanger made of stainless steel. Generally, 7~10℃ water is used for cooling; 40~45℃ warm water is used for heating.

Electrode and electrode liquid circulation system

The electrode and electrode liquid circulation system removes the remaining neutralizing acid (hac) produced by electrophoresis, keeps the neutralizing concentration stable, and achieves the purpose of electrophoretic coating and maintaining the acid concentration in the tank. There are two kinds of electrodes: diaphragm electrode and bare electrode, and the electrode is made of acid-resistant stainless steel (sus316, etc.).

DC Electrophoresis Power Supply

The rectifier generates direct current for electrophoresis coating current. In the case of cathodic electrophoresis, the body is used as a (-1) pole, which is energized through the insulated busbar and the wire on the side of the frame. In the case of continuous production, a large-capacity power supply is required.

Spare tank (replacement tank)

It is used to empty the electrophoresis tank for regular cleaning and maintenance, and for temporary storage of the tank liquid. To prevent precipitation and deterioration of the tank liquid, it is also required to circulate and agitate.

Electrophoresis coating room

Protect the electrophoresis tank against electric shock and solvent vapor diffusion, and equipped with exhaust air exchange system.

Electrophoretic cleaning equipment

Remove the floating paint attached to the car body, recycle the paint, improve the appearance quality of the coating film, adopt UF liquid spraying and immersion washing, and return to the main tank in reverse process.

Electrophoretic paint ultrafiltration recovery device

Provides cleaning solution after electrophoresis, recovers paint to remove impurity ions in the tank solution, reduces the conductivity of the tank solution, adopts RO device to purify UF liquid instead of pure water, and realizes the fully closed situation.